What Exactly is a Turnkey Solution?

It seems that the current use of the word first rose to prominence in the construction industry. During a turnkey project, the construction company was in charge of planning, regulation, monitoring & construction, interior design and even furniture acquisition. At the end of the project, all the customer had to do was take the “key”, “turn” it inside the door, and enter the apartment.

One of the most prominent features of this method is responsibility. The turnkey supplier offered full accountability for the entire supply chain, from architect to carpenter, and was responsible for fixing any inadequacies, even after the property was turned over to its rightful owners.

The Turnkey Solution in Technology Companies

Over the past decades, tech companies have begun adopting various methods that aim to reduce operational overhead and market risk, while improving product quality. One of the leading methodologies was called LEAN. The LEAN methodology, which was established in the 90’s and was based on Toyota’s production management style, challenges organizations to work more effectively and waste less resources.

A Turnkey supplier, who is also known as a Contract Manufacturer, provides an end-to-end solution that implements corporate operations in effective and optimal fashion. The supplier relies on an improved operations structure, which includes the supply chain, quality and production departments, to transfer his customers’ procurement, production, quality and logistics to his own facility.

What this means is that the Turnkey supplier takes full responsibility for the supply chain and all sub-contractors, so that the customer can deal with a single supplier. The customer-turnkey supplier relationship is based on procurement orders and/or long-term agreements, in accordance with customer needs (JUST IN TIME). As such, the customer can feel free to manage minimal inventory and can therefore improve the company’s cash flow.

The turnkey supplier helps his customers to significantly minimize their operations, therefore allowing them to focus more on corporate strategy and product development and less on infrastructure and supply chain management.

In addition, this method significantly reduces exposure to market risks, minimizes overhead costs and facilitates a quick response to market needs.As a result, customers can easily adapt to both internal changes and external market developments.

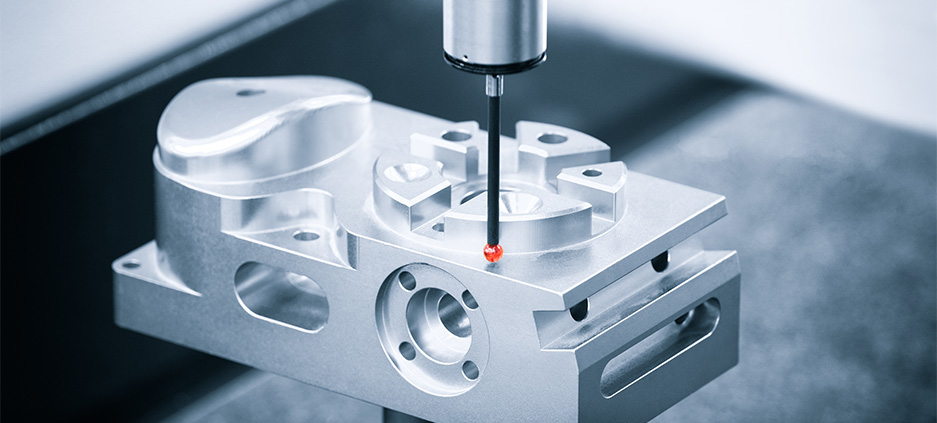

Zuk Systems – Comprehensive Solutions for Integrated Systems

In recent years, Turnkey suppliers have developed additional capabilities that extend beyond operations and procurement – for example, advanced engineering services. Zuk Systems specializes in unique technologies such as mechanics, optics, control, motion and pneumatics, and provides engineering services that include NPI (New Product Introduction), engineering design improvements and reverse engineering.

Yet another advantage of working with a Turnkey contractor is their exposure to a wide range of industries = risk distribution. Our customers come from a wide variety of industries, including industrial printing, food & beverage, veterinary services, robotic systems, automation, semiconductors, defense, printed circuit boards, medical systems, and more. This diverse activity allows us to operate linearly and to provide services to customers that operate in industries with high market fluctuations, as well as companies that experience deceleration or quick acceleration. We supply an operational core not only to large international corporations, but also to start-ups with a mature prototype that require professional operations and engineering support, in order to improve their prototype via an NPI process and facilitate quick and effective market penetration.

During the Turnkey work process, a vast amount of knowledge is transferred between the supplier and customer, creating a mutual dependency that requires an initial investment from both parties. Therefore, financial stability plays a key role when choosing a Turnkey supplier.

Conclusion

As the Turnkey supplier field continues to develop, service centers are expanding and offer a more flexible response at a more competitive price. As a result, more and more companies are beginning to understand